Madsis Engineering Software and Services for Industry

We design and develop software for the engineering applications of tomorrow!

Innovation is not a buzz-word, it is a way of thinking and working.

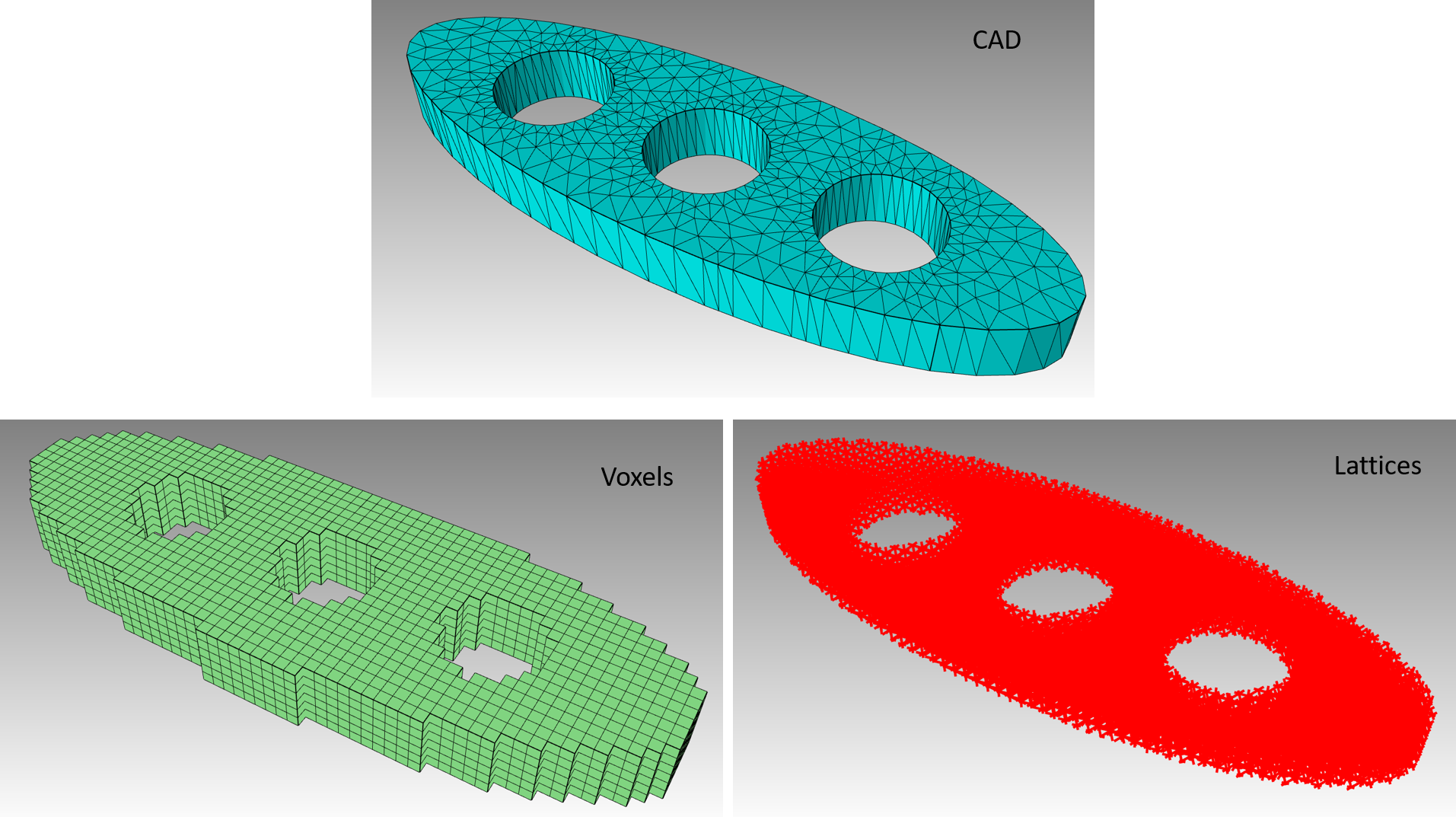

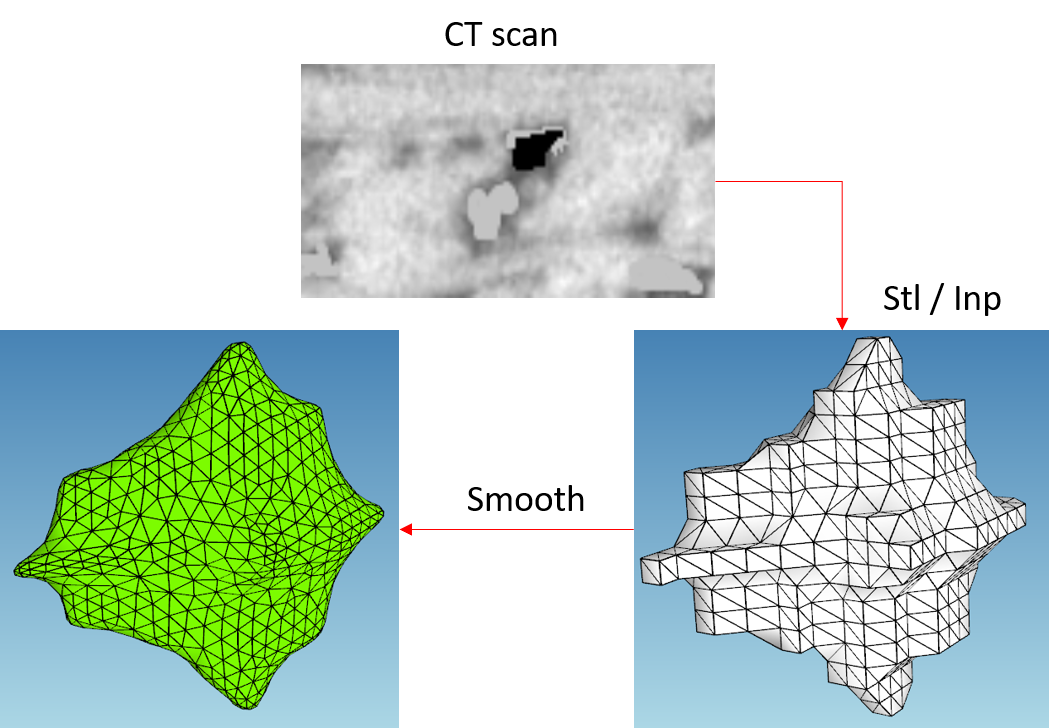

Nowadays innovation often requires software in one way or another. We can help you defining a scope, ideation and build-up a minimal viable product, prototype and integrate the innovation into an existing legacy.

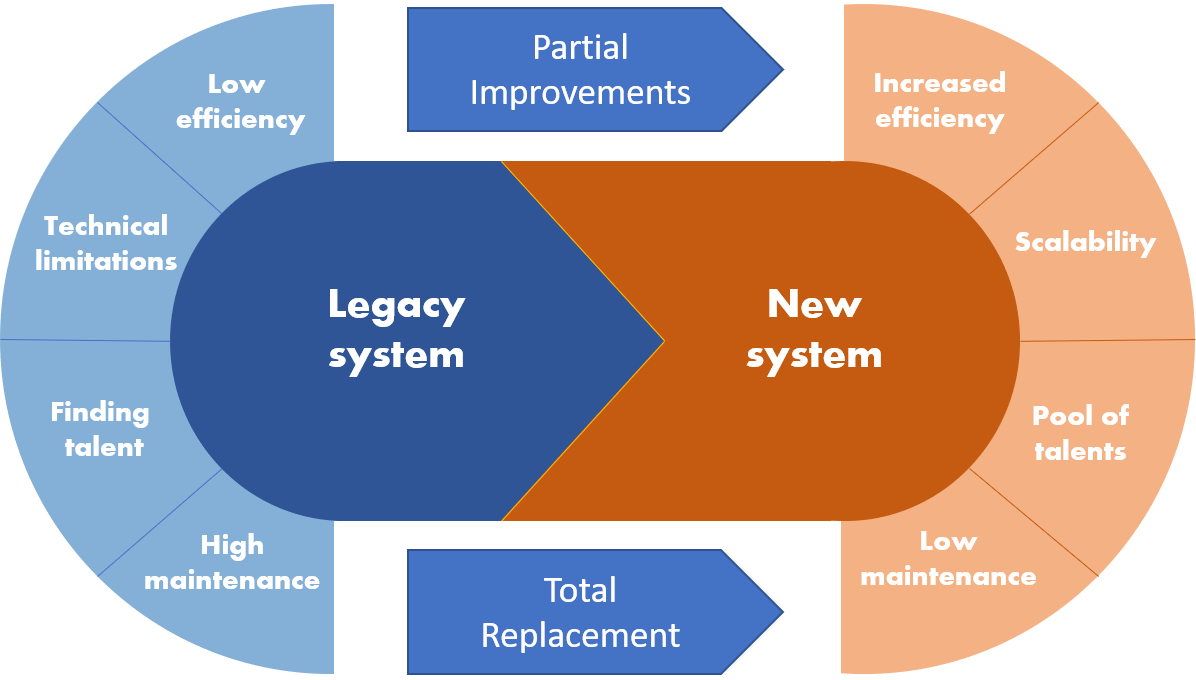

From legacy to state-of-the-art

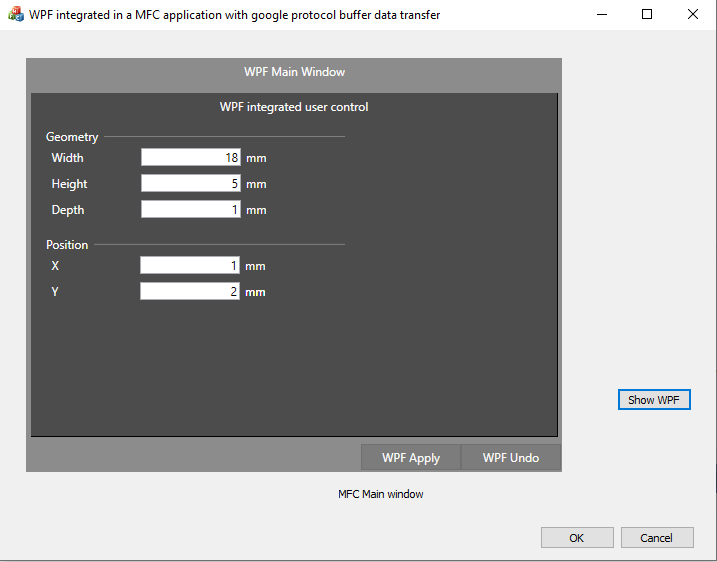

An existing legacy can sometimes be a blocking factor for technological innovation. Madsis has experience in integrating new technologies into an existing legacy in order to profit of both, the proven technology as well as the state-of-the-art. Madsis can guide the customer by analyzing the existing code base, and help setting up a roadmap and estimation for converting / keeping the existing technology and integrate the new one into it.